Endura Flap Dog Doors for Walls

- Regular price

- $339.99

- Sale price

- $339.99

- Regular price

-

- Unit price

- per

- Telescoping tunnel adjusts to walls 4 1/2" to 7 1/2" thick

- Superior insulation with single or double flaps, flexible in -40°F and resistant to 50 mph winds.

- Durable ABS locking cover is as strong as 16-gauge steel and securely blocks access when needed (inside frame only).

- Robust aluminum frame, available in white or black.

- Tall, slim flap design accommodates a wide range of pet sizes.

- Telescoping aluminum tunnel is secure, weather resistant, and easy-to-install.

- Lifetime warranty and 100% designed, engineered, and manufactured in the U.S.

Product Details

The Endura Flap Dog Doors for Walls with Wood Tunnel delivers premium performance and lasting durability. Engineered for walls 4 1/2" to 7/12" thick, with an option for deeper walls up to 13", these pet doors offer unmatched insulation and wind resistance.

Choose between single or double flaps, designed to stay flexible down to -40°F and remain sealed against 50 mph winds, thanks to strong magnets lining three sides.

The sleek aluminum frame, available in white or black, pairs with a rugged, all-metal telescoping tunnel that simplifies installation and provides a cleaner, more durable fit. The taller, slim flap design suits both large and small pets, and the included steel-strength ABS locking cover slides into place to block access when needed.

Built to last and backed by a lifetime warranty, this American-made pet door is a stylish, secure, and energy-efficient solution for your pet’s freedom. Plus, the easy-to-clean flap and provided installation videos and instructions make setup a breeze. Endura Flap isn’t just a pet door—it’s a long-term investment in your home’s comfort and your pet’s happiness.

Size Chart

- Small Single Flap: 6"w x 11"h Double Flap: 6"w x 10"h

- Medium Single Flap: 8"w x 15"h Double Flap: 8"w x 14"h

- Large Single Flap: 10"w x 19"h Double Flap: 10"w x 18"h

- Extra Large Single Flap: 12"w x 23"h Double Flap: 12"w x 22"h

- XX Large Single Flap: 14" w x 27" h Double Flap: 14" w x 26" h

Flap Dimensions:

Single Flap:6"w x 11"h

Double Flap:6"w x 10"h

The entry way your dog goes through.

Outside Frame Dimensions

10 1/8"w x 16 3/4"h

The outer edge of the pet door.

Rough Cut Out:

8 5/8" w x 15" h

The size of the hole needed to fit your pet door into your wall.

Flap Dimensions:

Single Flap:8"w x 15"h

Double Flap:8"w x 14"h

The entry way your dog goes through.

Outside Frame Dimensions

12 3/16"w x 20 3/4"h

The outer edge of the pet door.

Rough Cut Out:

10 3/8" w x 19" h

The size of the hole needed to fit your pet door into your wall.

Flap Dimensions:

Single Flap:10"w x 19"h

Double Flap:10"w x 18"h

The entry way your dog goes through.

Outside Frame Dimensions

14 3/16"w x 24 3/4"h

The outer edge of the pet door.

Rough Cut Out:

12 1/2" w x 23 1/16" h

The size of the hole needed to fit your pet door into your wall.

Flap Dimensions:

Single Flap:12"w x 23"h

Double Flap:12"w x 22"h

The entry way your dog goes through.

Outside Frame Dimensions

16 1/4"w x 28 7/8"h

The outer edge of the pet door.

Rough Cut Out:

14 11/16" w x 27 1/16" h

The size of the hole needed to fit your pet door into your wall.

Flap Dimensions:

Single Flap:14" w x 27" h

Double Flap:14" w x 26" h

The entry way your dog goes through.

Outside Frame Dimensions

18 1/4" w x 32 7/8" h

The outer edge of the pet door.

Rough Cut Out:

16 13/16" w x 31 3/16" h

The size of the hole needed to fit your pet door into your wall.

| Flap Size | Flap Dimension | Rough Cut Out | Outside Frame Dimension | Recommended Pet Height |

|---|---|---|---|---|

| Small | (Single) 6" w x 11" h | 8 5/8" w x 15" h | 10 1/8 w x 16 3/4" h | 9" - 16" |

| (Double) 6" w x 10" h | 8" - 14" | |||

| Medium | (Single) 8" w x 15" h | 10 3/8" w x 19" h | 12 3/16" w x 20 3/4" h | 9" - 22" |

| (Double) 8" w x 14" h | 8" - 21" | |||

| Large | (Single) 10" w x 19" h | 12 1/2" w x 23 1/16" h | 14 3/16" w x 24 3/4" h | 9" - 28" |

| (Double) 10" w x 18" h | 8" - 27" | |||

| Extra Large | (Single) 12" w x 23" h | 14 11/16" w x 27 1/16" h | 16 1/4" w x 28 7/8" h | 9" - 36" |

| (Double) 12" w x 22" h | 8" - 34" | |||

| XX Large | (Single) 14" w x 27" h | 16 13/16" w x 31 3/16" h | 18 1/4" w x 32 7/8" h | 8" - 42" |

| (Double) 14" w x 26" h | 8" - 41" |

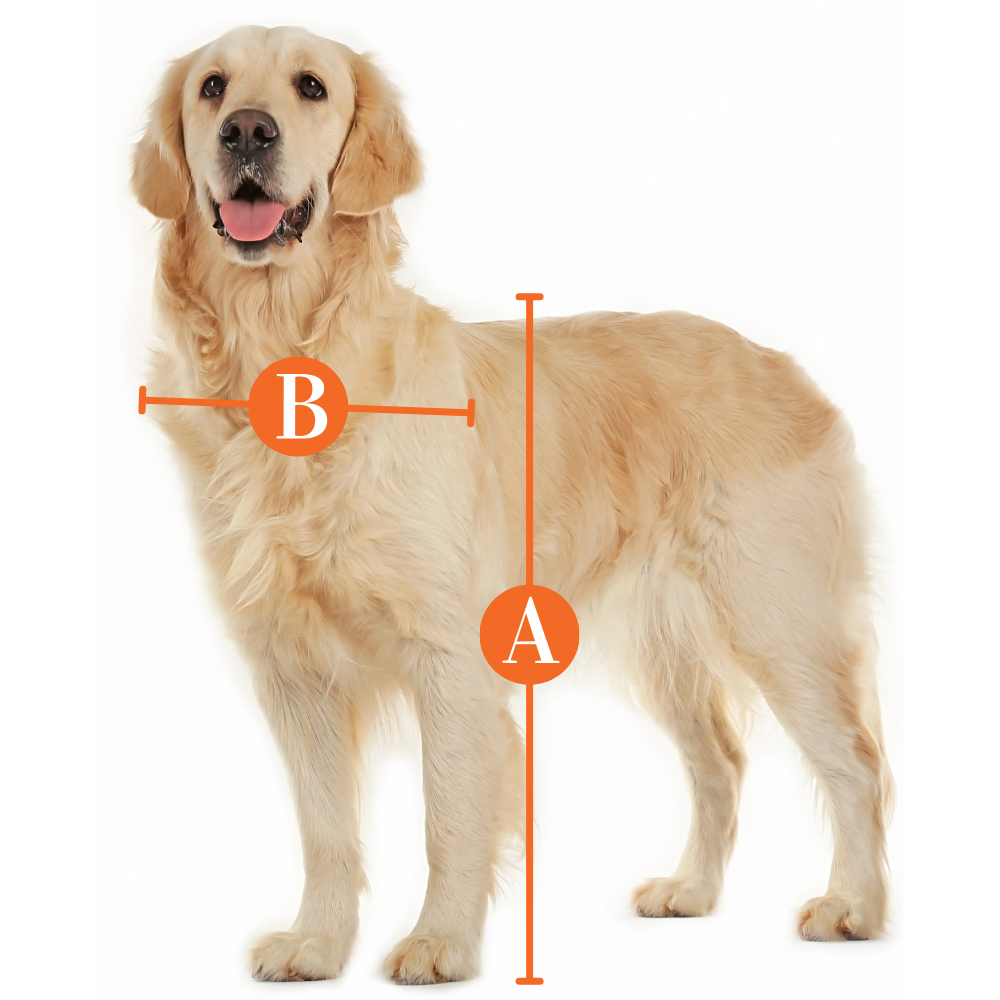

Do not know which size to get? Here is a measurement guide to help you out

Number of Flaps:

- 1 - Single Flap: On inside of wall (same side as locking cover)

- 2 - Double Flap: One on each side. The included dead-air-space and extra flap add significantly to the already considerable insulation and sealing values.

Find The Best Pet Door Size For My Pet

A

Pet Height: inches

B

Pet Width: inches

Installation Instructions

Single Flap Wall Mount

Parts

- Inner frame with tunnel

- Outer frame with tunnel

- Locking cover

- Inner wall template

- Caulking

- Sheet metal screws

- Outer wall transfer template with level and pencil

Tools

- Measuring tape

- Electric drill/driver (philips head and drill bit for outer wall)

- Safety gear

- Stud finder

- Drywall knife (or other tool for cutting the inside wall)

- Saw (for the outside wall, pick one that works with your wall material)

- Caulking gun

- Clamp (or an extra set of hands!)

Take a few minutes to read these instructions from start to finish— it’s worth it! If the thought of cutting a hole in your house makes your palms sweaty, no shame in bringing in a pro to handle it!

Step 1 Measure Your Pet

- First up, measure your pet and mark the wall 3 inches above their height—it’s the sweet spot for lining up the template.

Step 2 Prepare Wall for Installation

- Find a wall spot with a stud on one side and nothing scary like pipes or wires lurking behind it.

Step 3 Make the Rough Cutout

- Line up the template with the stud, level as needed, and tape it down so it doesn’t go anywhere.

- Trace the outline of the template. Once you’ve got your full template traced, remove it and finish cutting along the lines.

Step 4 MARK DRILL POINTS FOR THE OUTER WALL

- Take the included Outer Wall marking Template and place it on the bottom left corner of the tunnel on the outside frame, where it will gently touch the inside of the outer wall. The outside trim frame has the larger tunnel, and no flap!

- From inside the house, slide the outside frame partway into the wall opening until the Outer Wall Template reaches the exterior wall.

- Using the small hole in the template and the provided pencil, mark the drill point.

- Repeat this process for the top right corner: position the outer wall marking template, align it properly, and mark the spot.

Step 5 DRILL THROUGH THE OUTER WALL

- Once both points are marked, drill straight through the wall at each location. These holes will guide you when installing the outer frame in the next step.

Step 6 MARK WHERE TO CUT THE OUTER WALL

- Head outside and line up the outer wall marking template with the holes you drilled earlier. Level the jig, then mark its corners on your wall.

- After marking your two corners, grab the cardboard template and line it up with the corners you marked to trace out the cut lines.

- Then, remove the template and get your saw ready for the next step.

Step 7 CUT OUTER WALL OPENING

- Cut the outer wall opening using the appropriate tool for your wall type (e.g., stucco, siding, etc.).

- Take your time cutting along the lines—it’s all about accuracy here!

Step 8 INSERT PET DOOR FRAMES

- Slide both frames (inside and outside) into the wall opening and telescope them together until snug against both walls. It is easier to insert the outside trim frame first, and this step is where an extra set of hands can be super helpful!

Step 9 SECURE THE FRAMES TO THE STUD

- Get the frames leveled and aligned, then grab a helper to gently squeeze them together from both sides of the wall. Or use a large clamp, which can also hold open the flap for you.

- While maintaining this pressure, drive two screws through the tunnels into the stud side—position one screw about one-third from the top and the other about one-third from the bottom. This ensures a snug and secure fit.

- Repeat on the other side, even if there’s no stud—it will still hold securely.

Step 10 TEST YOUR WORK

- Test the flap to ensure smooth operation. It should swing freely in both directions. If the flap catches at all, make adjustments before sealing the frame in the next step.

Step 11 SEAL THE FRAME

- To ensure your pet door is weather-tight and energy-efficient, follow these sealing steps:

- Seal the Interior Frame: Apply a bead of silicone caulk between the interior frame and the metal tunnel.

- Seal the Tunnel Seams: Apply a bead of caulk along the seams where the two telescoping metal tunnel sections meet. This will prevent air or water infiltration.

- Seal the Exterior Frame: On the outside of your home, apply caulk between the exterior frame and the wall. Be sure to seal the top and both sides, but not the bottom. You want that open for water to drain out.

- Seriously - don’t seal the bottom, that’s your drainage zone!

- Now, stand back, let your pet strut through their new door, and take all the credit. Well done!

Double Flap Wall Mount

Parts

- Inner frame with tunnel

- Outer frame with tunnel

- Locking cover

- Inner wall template

- Caulking

- Sheet metal screws

- Outer wall transfer template with level and pencil

Tools

- Measuring tape

- Electric drill/driver (philips head and drill bit for outer wall)

- Safety gear

- Stud finder

- Drywall knife (or other tool for cutting the inside wall)

- Saw (for the outside wall, pick one that works with your wall material)

- Caulking gun

- Clamp (or an extra set of hands!)

Take a few minutes to read these instructions from start to finish— it’s worth it! If the thought of cutting a hole in your house makes your palms sweaty, no shame in bringing in a pro to handle it!

Step 1 Measure Your Pet

- First up, measure your pet and mark the wall 3 inches above their height—it’s the sweet spot for lining up the template.

Step 2 Prepare Wall for Installation

- Find a wall spot with a stud on one side and nothing scary like pipes or wires lurking behind it.

Step 3 Make the Rough Cutout

- Line up the template with the stud, level as needed, and tape it down so it doesn’t go anywhere.

- Trace the outline of the template. Once you’ve got your full template traced, remove it and finish cutting along the lines.

Step 4 MARK DRILL POINTS FOR THE OUTER WALL

- Take the included Outer Wall marking Template and place it on the bottom left corner of the tunnel on the outside frame, where it will gently touch the inside of the outer wall. The outside frame has the larger tunnel, and will not have the locking cover in it!

- From inside the house, slide the outside frame partway into the wall opening until the Outer Wall Template reaches the exterior wall.

- Using the small hole in the template and the provided pencil, mark the drill point.

- Repeat this process for the top right corner: position the outer wall marking template, align it properly, and mark the spot.

Step 5 DRILL THROUGH THE OUTER WALL

- Once both points are marked, drill straight through the wall at each location. These holes will guide you when installing the outer frame in the next step.

Step 6 MARK WHERE TO CUT THE OUTER WALL

- Head outside and line up the outer wall marking template with the holes you drilled earlier. Level the jig, then mark its corners on your wall.

- After marking your two corners, grab the cardboard template and line it up with the corners you marked to trace out the cut lines.

- Then, remove the template and get your saw ready for the next step.

Step 7 CUT OUTER WALL OPENING

- Cut the outer wall opening using the appropriate tool for your wall type (e.g., stucco, siding, etc.).

- Take your time cutting along the lines—it’s all about accuracy here!

Step 8 INSERT PET DOOR FRAMES

- Slide both frames (inside and outside) into the wall opening and telescope them together until snug against both walls. It is easier to insert the outside trim frame first, and this step is where an extra set of hands can be super helpful!

Step 9 SECURE THE FRAMES TO THE STUD

- Get the frames leveled and aligned, then grab a helper to gently squeeze them together from both sides of the wall. Or use a large clamp, which can also hold open the flap for you.

- While maintaining this pressure, drive two screws through the tunnels into the stud side—position one screw about one-third from the top and the other about one-third from the bottom. This ensures a snug and secure fit.

- Repeat on the other side, even if there’s no stud—it will still hold securely.

Step 10 TEST YOUR WORK

- Test the flap to ensure smooth operation. It should swing freely in both directions. If the flap catches at all, make adjustments before sealing the frame in the next step.

Step 11 SEAL THE FRAME

- To ensure your pet door is weather-tight and energy-efficient, follow these sealing steps:

- Seal the Interior Frame: Apply a bead of silicone caulk between the interior frame and the metal tunnel.

- Seal the Tunnel Seams: Apply a bead of caulk along the seams where the two telescoping metal tunnel sections meet. This will prevent air or water infiltration.

- Seal the Exterior Frame: On the outside of your home, apply caulk between the exterior frame and the wall. Be sure to seal the top and both sides, but not the bottom. You want that open for water to drain out.

- Seriously - don’t seal the bottom, that’s your drainage zone!

- Now, stand back, let your pet strut through their new door, and take all the credit. Well done!

Videos

The Endura Flap Pet Door

Design of the Endura Flap

Removing Side Magnets

Adjusting Your Endura Flap® Magnet Strength

The Leaf Blower Test

FAQ

|

Can I get this pet door with a clear flap? The Endura Flap is only available with a translucent flap, but if you want a similar high quality, aluminum frame pet door that has a clear flap, we highly recommend the Liberty Pet Door for Walls. |

|

I want to get the large pet door for my dog, but I am concerned about a person fitting through an x-large door. All Endura Flap Pet Doors come with a locking cover. This cover can be used to keep your pet inside by blocking access to the doggie door. It also can be used to keep intruders from entering your home. It is made from a special polymer that is as strong as 1/16" sheet of steel. If you need to, you can purchase additional Endura Flap locking covers.We also have a product called the Watchdog Steel Security Pet Door Cover that provides maximum security for any pet door, complete with a combination lock and all. The cover comes in sizes large enough to fit even the XL dog doors for wall mount.Security consultants agree that dogs are a good burglar deterrent, especially one that barks. If you want to leave your pet door open make sure the gate to access your yard is locked and you post a “Beware of Dog” sign. |

|

Can a large dog & cat use the same double flap door flaps? We recommend cats use the Endura Flap Cat Doors for Walls. Our Endura Flap wall mount pet door has a strong magnetic seal which may be too strong for a cat. However, if you have cats and dogs sharing a door, you can decrease the magnetic resistance of the threshold on large and extra large sizes making it easier for a cat to use. For small or medium pet doors you can offset the magnets slightly which can also decrease the magnetic strength. |

|

I have a small and large dog sharing this door. Will my small dog be able to open the flaps on the extra large double flap dog door? It depends on the tenacity of your small dog. With the Endura flap door for walls you can decrease the magnetic resistance of the threshold on large and extra large sizes making it easier for your small dog to use. You will also want to make sure the door is mounted low enough for the small dog to walk through and high enough to clear the large dog's back. This may mean purchasing a larger flap. |

|

Is the flap on the interior or exterior frame for single flap model? For the single flap wall mount, the flap is attached to the interior frame. If you live in a very cold climate, we'd recommend the double flap model to keep snow out of the pet door tunnel. |

|

How do I know what size is best for my dog? When installing the Endura Flap wall door you want it to clear the top of your dog's back by 1-2 inches, minimum. You also want the step over to be comfortable. Lastly you want the width to allow your pet to go through without touching the sides. Here's a measurement guide with tips on how to determine the correct size. |

|

Are the panels/flaps flexible? Seems like it would trap a dog if it backed up. The Endura Flap is slightly more rigid than other economy style flaps, but it is a safe, soft, flexible flap. It remains flexible in temperatures as low as -40°F. |

|

Is a single flap enough for extreme winter weather? A single Endura Flap flap is on the interior frame. It is energy-efficient and capable of withstanding winds up to 50 mph. However for extreme weather, we recommend the double flap which increases the efficiency. For timid pets you can remove the magnets on the interior flap or remove the flap completely. |

|

Does the door sound very loud when the dog goes in or out? When the flap gets to its resting place there is a snapping sound when the magnets employ. This sound let's you know the door is doing its job sealing out the elements and keeping your heated or cooled air inside. |

|

I do not have to contend with wind or rain. If I buy the single flap version of the wall dog door is it possible to add the second flap in the future? It is possible. Please reach out to Customer Service to order an exterior frame and flap. Note, you cannot change an Endura Flap Door Mount to a Wall Mount. |

|

What side does the locking cover slide in? All locking covers slide in from the top. If you purchase a double flap model, the locking cover can be used on the inside or outside frame. If you purchase a single flap, the locking cover is on the interior frame (the side closest to the inside of your home). |

|

Other brands of pet doors with plastic flaps always warp and thus let in air. How do these flaps hold up over time? The Endura Flap is made with a special polymer called Polyolefin. It remains safe, soft and flexible in temperatures as low as -40°F. It does not yellow nor harden in the sun. The patented magnetic design ensures the door door seals well for years. In fact, the pet door and flap are backed by a Lifetime warranty. |

|

Are replacement flaps available? Yes, we carry Endura Replacement Flaps. They will work for all Endura models (wall mounts, doggy door mounts, kennel doors, window sashes, and sliding glass door patio pet doors). |

|

Why is there a difference in flap size for the single versus the double flap models? Each flap is 7/8" thick, and when a pet goes through a dual flap pet door, the flaps stack on top of each other. This makes it so that there is a loss of about 1" of space at the top as they enter or exit. To account for this and help customers pick the best size for their pets, we subtract an inch from the listed heights of the double flap models. |

|

Is the patio pacific Endura Flap large wall mount - double flap large enough for a lab? Due to variations in individual pet sizes within a breed, we generally prefer to go by height and width instead of breed. You can visit this page on our website to learn how to measure for a pet door. |

|

Is the Endura Door for Walls easy to install? Ease of installation is very subjective, and it depends on skill set or access to certain tools that might be needed. The installation of a pet door into a door is easier than installing it through a wall; however installing it into a door is more complicated than putting a pet door into a sliding door track. We recommend a contractor for installations that involve cutting into drywall. |

|

What is the flap size for the Endura Dog Doors for Walls-Large-Double Flap? The actual flap on the Large size Endura Flap is about 10"w x 20"h. However, the opening for the pet to use on the single flap is 10"w x 19"h and on the double flap is 10”w x 18”h (due to the thickness of two flaps). |

|

Can I just get the Endura wall kit? We do have those, but you will need to reach out to our customer service team. For other Endura replacement pet products, see Endura replacement flaps and parts. |

|

How much does shipping cost? Shipping is calculated at checkout. |

Warranty

Warranty Type: Lifetime

Duration: Lifetime of the product.

Coverage: Defects in materials and workmanship under standard regular use.

Exclusions:

Damage caused by misuse or not using the product as intended.

Improper installation.

Damage caused by chewing.

Customer Reviews

Size Chart

- Small Single Flap: 6"w x 11"h Double Flap: 6"w x 10"h

- Medium Single Flap: 8"w x 15"h Double Flap: 8"w x 14"h

- Large Single Flap: 10"w x 19"h Double Flap: 10"w x 18"h

- Extra Large Single Flap: 12"w x 23"h Double Flap: 12"w x 22"h

- XX Large Single Flap: 14" w x 27" h Double Flap: 14" w x 26" h

Flap Dimensions:

Single Flap:6"w x 11"h

Double Flap:6"w x 10"h

The entry way your dog goes through.

Outside Frame Dimensions

10 1/8"w x 16 3/4"h

The outer edge of the pet door.

Rough Cut Out:

8 5/8" w x 15" h

The size of the hole needed to fit your pet door into your wall.

Flap Dimensions:

Single Flap:8"w x 15"h

Double Flap:8"w x 14"h

The entry way your dog goes through.

Outside Frame Dimensions

12 3/16"w x 20 3/4"h

The outer edge of the pet door.

Rough Cut Out:

10 3/8" w x 19" h

The size of the hole needed to fit your pet door into your wall.

Flap Dimensions:

Single Flap:10"w x 19"h

Double Flap:10"w x 18"h

The entry way your dog goes through.

Outside Frame Dimensions

14 3/16"w x 24 3/4"h

The outer edge of the pet door.

Rough Cut Out:

12 1/2" w x 23 1/16" h

The size of the hole needed to fit your pet door into your wall.

Flap Dimensions:

Single Flap:12"w x 23"h

Double Flap:12"w x 22"h

The entry way your dog goes through.

Outside Frame Dimensions

16 1/4"w x 28 7/8"h

The outer edge of the pet door.

Rough Cut Out:

14 11/16" w x 27 1/16" h

The size of the hole needed to fit your pet door into your wall.

Flap Dimensions:

Single Flap:14" w x 27" h

Double Flap:14" w x 26" h

The entry way your dog goes through.

Outside Frame Dimensions

18 1/4" w x 32 7/8" h

The outer edge of the pet door.

Rough Cut Out:

16 13/16" w x 31 3/16" h

The size of the hole needed to fit your pet door into your wall.

| Flap Size | Flap Dimension | Rough Cut Out | Outside Frame Dimension | Recommended Pet Height |

|---|---|---|---|---|

| Small | (Single) 6" w x 11" h | 8 5/8" w x 15" h | 10 1/8 w x 16 3/4" h | 9" - 16" |

| (Double) 6" w x 10" h | 8" - 14" | |||

| Medium | (Single) 8" w x 15" h | 10 3/8" w x 19" h | 12 3/16" w x 20 3/4" h | 9" - 22" |

| (Double) 8" w x 14" h | 8" - 21" | |||

| Large | (Single) 10" w x 19" h | 12 1/2" w x 23 1/16" h | 14 3/16" w x 24 3/4" h | 9" - 28" |

| (Double) 10" w x 18" h | 8" - 27" | |||

| Extra Large | (Single) 12" w x 23" h | 14 11/16" w x 27 1/16" h | 16 1/4" w x 28 7/8" h | 9" - 36" |

| (Double) 12" w x 22" h | 8" - 34" | |||

| XX Large | (Single) 14" w x 27" h | 16 13/16" w x 31 3/16" h | 18 1/4" w x 32 7/8" h | 8" - 42" |

| (Double) 14" w x 26" h | 8" - 41" |

Do not know which size to get? Here is a measurement guide to help you out

Number of Flaps:

- 1 - Single Flap: On inside of wall (same side as locking cover)

- 2 - Double Flap: One on each side. The included dead-air-space and extra flap add significantly to the already considerable insulation and sealing values.

Find The Best Pet Door Size For My Pet

A

Pet Height: inches

B

Pet Width: inches

Installation Instructions

Single Flap Wall Mount

Parts

- Inner frame with tunnel

- Outer frame with tunnel

- Locking cover

- Inner wall template

- Caulking

- Sheet metal screws

- Outer wall transfer template with level and pencil

Tools

- Measuring tape

- Electric drill/driver (philips head and drill bit for outer wall)

- Safety gear

- Stud finder

- Drywall knife (or other tool for cutting the inside wall)

- Saw (for the outside wall, pick one that works with your wall material)

- Caulking gun

- Clamp (or an extra set of hands!)

Take a few minutes to read these instructions from start to finish— it’s worth it! If the thought of cutting a hole in your house makes your palms sweaty, no shame in bringing in a pro to handle it!

Step 1 Measure Your Pet

- First up, measure your pet and mark the wall 3 inches above their height—it’s the sweet spot for lining up the template.

Step 2 Prepare Wall for Installation

- Find a wall spot with a stud on one side and nothing scary like pipes or wires lurking behind it.

Step 3 Make the Rough Cutout

- Line up the template with the stud, level as needed, and tape it down so it doesn’t go anywhere.

- Trace the outline of the template. Once you’ve got your full template traced, remove it and finish cutting along the lines.

Step 4 MARK DRILL POINTS FOR THE OUTER WALL

- Take the included Outer Wall marking Template and place it on the bottom left corner of the tunnel on the outside frame, where it will gently touch the inside of the outer wall. The outside trim frame has the larger tunnel, and no flap!

- From inside the house, slide the outside frame partway into the wall opening until the Outer Wall Template reaches the exterior wall.

- Using the small hole in the template and the provided pencil, mark the drill point.

- Repeat this process for the top right corner: position the outer wall marking template, align it properly, and mark the spot.

Step 5 DRILL THROUGH THE OUTER WALL

- Once both points are marked, drill straight through the wall at each location. These holes will guide you when installing the outer frame in the next step.

Step 6 MARK WHERE TO CUT THE OUTER WALL

- Head outside and line up the outer wall marking template with the holes you drilled earlier. Level the jig, then mark its corners on your wall.

- After marking your two corners, grab the cardboard template and line it up with the corners you marked to trace out the cut lines.

- Then, remove the template and get your saw ready for the next step.

Step 7 CUT OUTER WALL OPENING

- Cut the outer wall opening using the appropriate tool for your wall type (e.g., stucco, siding, etc.).

- Take your time cutting along the lines—it’s all about accuracy here!

Step 8 INSERT PET DOOR FRAMES

- Slide both frames (inside and outside) into the wall opening and telescope them together until snug against both walls. It is easier to insert the outside trim frame first, and this step is where an extra set of hands can be super helpful!

Step 9 SECURE THE FRAMES TO THE STUD

- Get the frames leveled and aligned, then grab a helper to gently squeeze them together from both sides of the wall. Or use a large clamp, which can also hold open the flap for you.

- While maintaining this pressure, drive two screws through the tunnels into the stud side—position one screw about one-third from the top and the other about one-third from the bottom. This ensures a snug and secure fit.

- Repeat on the other side, even if there’s no stud—it will still hold securely.

Step 10 TEST YOUR WORK

- Test the flap to ensure smooth operation. It should swing freely in both directions. If the flap catches at all, make adjustments before sealing the frame in the next step.

Step 11 SEAL THE FRAME

- To ensure your pet door is weather-tight and energy-efficient, follow these sealing steps:

- Seal the Interior Frame: Apply a bead of silicone caulk between the interior frame and the metal tunnel.

- Seal the Tunnel Seams: Apply a bead of caulk along the seams where the two telescoping metal tunnel sections meet. This will prevent air or water infiltration.

- Seal the Exterior Frame: On the outside of your home, apply caulk between the exterior frame and the wall. Be sure to seal the top and both sides, but not the bottom. You want that open for water to drain out.

- Seriously - don’t seal the bottom, that’s your drainage zone!

- Now, stand back, let your pet strut through their new door, and take all the credit. Well done!

Double Flap Wall Mount

Parts

- Inner frame with tunnel

- Outer frame with tunnel

- Locking cover

- Inner wall template

- Caulking

- Sheet metal screws

- Outer wall transfer template with level and pencil

Tools

- Measuring tape

- Electric drill/driver (philips head and drill bit for outer wall)

- Safety gear

- Stud finder

- Drywall knife (or other tool for cutting the inside wall)

- Saw (for the outside wall, pick one that works with your wall material)

- Caulking gun

- Clamp (or an extra set of hands!)

Take a few minutes to read these instructions from start to finish— it’s worth it! If the thought of cutting a hole in your house makes your palms sweaty, no shame in bringing in a pro to handle it!

Step 1 Measure Your Pet

- First up, measure your pet and mark the wall 3 inches above their height—it’s the sweet spot for lining up the template.

Step 2 Prepare Wall for Installation

- Find a wall spot with a stud on one side and nothing scary like pipes or wires lurking behind it.

Step 3 Make the Rough Cutout

- Line up the template with the stud, level as needed, and tape it down so it doesn’t go anywhere.

- Trace the outline of the template. Once you’ve got your full template traced, remove it and finish cutting along the lines.

Step 4 MARK DRILL POINTS FOR THE OUTER WALL

- Take the included Outer Wall marking Template and place it on the bottom left corner of the tunnel on the outside frame, where it will gently touch the inside of the outer wall. The outside frame has the larger tunnel, and will not have the locking cover in it!

- From inside the house, slide the outside frame partway into the wall opening until the Outer Wall Template reaches the exterior wall.

- Using the small hole in the template and the provided pencil, mark the drill point.

- Repeat this process for the top right corner: position the outer wall marking template, align it properly, and mark the spot.

Step 5 DRILL THROUGH THE OUTER WALL

- Once both points are marked, drill straight through the wall at each location. These holes will guide you when installing the outer frame in the next step.

Step 6 MARK WHERE TO CUT THE OUTER WALL

- Head outside and line up the outer wall marking template with the holes you drilled earlier. Level the jig, then mark its corners on your wall.

- After marking your two corners, grab the cardboard template and line it up with the corners you marked to trace out the cut lines.

- Then, remove the template and get your saw ready for the next step.

Step 7 CUT OUTER WALL OPENING

- Cut the outer wall opening using the appropriate tool for your wall type (e.g., stucco, siding, etc.).

- Take your time cutting along the lines—it’s all about accuracy here!

Step 8 INSERT PET DOOR FRAMES

- Slide both frames (inside and outside) into the wall opening and telescope them together until snug against both walls. It is easier to insert the outside trim frame first, and this step is where an extra set of hands can be super helpful!

Step 9 SECURE THE FRAMES TO THE STUD

- Get the frames leveled and aligned, then grab a helper to gently squeeze them together from both sides of the wall. Or use a large clamp, which can also hold open the flap for you.

- While maintaining this pressure, drive two screws through the tunnels into the stud side—position one screw about one-third from the top and the other about one-third from the bottom. This ensures a snug and secure fit.

- Repeat on the other side, even if there’s no stud—it will still hold securely.

Step 10 TEST YOUR WORK

- Test the flap to ensure smooth operation. It should swing freely in both directions. If the flap catches at all, make adjustments before sealing the frame in the next step.

Step 11 SEAL THE FRAME

- To ensure your pet door is weather-tight and energy-efficient, follow these sealing steps:

- Seal the Interior Frame: Apply a bead of silicone caulk between the interior frame and the metal tunnel.

- Seal the Tunnel Seams: Apply a bead of caulk along the seams where the two telescoping metal tunnel sections meet. This will prevent air or water infiltration.

- Seal the Exterior Frame: On the outside of your home, apply caulk between the exterior frame and the wall. Be sure to seal the top and both sides, but not the bottom. You want that open for water to drain out.

- Seriously - don’t seal the bottom, that’s your drainage zone!

- Now, stand back, let your pet strut through their new door, and take all the credit. Well done!

Videos

The Endura Flap Pet Door

Design of the Endura Flap

Removing Side Magnets

Adjusting Your Endura Flap® Magnet Strength

The Leaf Blower Test

FAQ

|

Can I get this pet door with a clear flap? The Endura Flap is only available with a translucent flap, but if you want a similar high quality, aluminum frame pet door that has a clear flap, we highly recommend the Liberty Pet Door for Walls. |

|

I want to get the large pet door for my dog, but I am concerned about a person fitting through an x-large door. All Endura Flap Pet Doors come with a locking cover. This cover can be used to keep your pet inside by blocking access to the doggie door. It also can be used to keep intruders from entering your home. It is made from a special polymer that is as strong as 1/16" sheet of steel. If you need to, you can purchase additional Endura Flap locking covers.We also have a product called the Watchdog Steel Security Pet Door Cover that provides maximum security for any pet door, complete with a combination lock and all. The cover comes in sizes large enough to fit even the XL dog doors for wall mount.Security consultants agree that dogs are a good burglar deterrent, especially one that barks. If you want to leave your pet door open make sure the gate to access your yard is locked and you post a “Beware of Dog” sign. |

|

Can a large dog & cat use the same double flap door flaps? We recommend cats use the Endura Flap Cat Doors for Walls. Our Endura Flap wall mount pet door has a strong magnetic seal which may be too strong for a cat. However, if you have cats and dogs sharing a door, you can decrease the magnetic resistance of the threshold on large and extra large sizes making it easier for a cat to use. For small or medium pet doors you can offset the magnets slightly which can also decrease the magnetic strength. |

|

I have a small and large dog sharing this door. Will my small dog be able to open the flaps on the extra large double flap dog door? It depends on the tenacity of your small dog. With the Endura flap door for walls you can decrease the magnetic resistance of the threshold on large and extra large sizes making it easier for your small dog to use. You will also want to make sure the door is mounted low enough for the small dog to walk through and high enough to clear the large dog's back. This may mean purchasing a larger flap. |

|

Is the flap on the interior or exterior frame for single flap model? For the single flap wall mount, the flap is attached to the interior frame. If you live in a very cold climate, we'd recommend the double flap model to keep snow out of the pet door tunnel. |

|

How do I know what size is best for my dog? When installing the Endura Flap wall door you want it to clear the top of your dog's back by 1-2 inches, minimum. You also want the step over to be comfortable. Lastly you want the width to allow your pet to go through without touching the sides. Here's a measurement guide with tips on how to determine the correct size. |

|

Are the panels/flaps flexible? Seems like it would trap a dog if it backed up. The Endura Flap is slightly more rigid than other economy style flaps, but it is a safe, soft, flexible flap. It remains flexible in temperatures as low as -40°F. |

|

Is a single flap enough for extreme winter weather? A single Endura Flap flap is on the interior frame. It is energy-efficient and capable of withstanding winds up to 50 mph. However for extreme weather, we recommend the double flap which increases the efficiency. For timid pets you can remove the magnets on the interior flap or remove the flap completely. |

|

Does the door sound very loud when the dog goes in or out? When the flap gets to its resting place there is a snapping sound when the magnets employ. This sound let's you know the door is doing its job sealing out the elements and keeping your heated or cooled air inside. |

|

I do not have to contend with wind or rain. If I buy the single flap version of the wall dog door is it possible to add the second flap in the future? It is possible. Please reach out to Customer Service to order an exterior frame and flap. Note, you cannot change an Endura Flap Door Mount to a Wall Mount. |

|

What side does the locking cover slide in? All locking covers slide in from the top. If you purchase a double flap model, the locking cover can be used on the inside or outside frame. If you purchase a single flap, the locking cover is on the interior frame (the side closest to the inside of your home). |

|

Other brands of pet doors with plastic flaps always warp and thus let in air. How do these flaps hold up over time? The Endura Flap is made with a special polymer called Polyolefin. It remains safe, soft and flexible in temperatures as low as -40°F. It does not yellow nor harden in the sun. The patented magnetic design ensures the door door seals well for years. In fact, the pet door and flap are backed by a Lifetime warranty. |

|

Are replacement flaps available? Yes, we carry Endura Replacement Flaps. They will work for all Endura models (wall mounts, doggy door mounts, kennel doors, window sashes, and sliding glass door patio pet doors). |

|

Why is there a difference in flap size for the single versus the double flap models? Each flap is 7/8" thick, and when a pet goes through a dual flap pet door, the flaps stack on top of each other. This makes it so that there is a loss of about 1" of space at the top as they enter or exit. To account for this and help customers pick the best size for their pets, we subtract an inch from the listed heights of the double flap models. |

|

Is the patio pacific Endura Flap large wall mount - double flap large enough for a lab? Due to variations in individual pet sizes within a breed, we generally prefer to go by height and width instead of breed. You can visit this page on our website to learn how to measure for a pet door. |

|

Is the Endura Door for Walls easy to install? Ease of installation is very subjective, and it depends on skill set or access to certain tools that might be needed. The installation of a pet door into a door is easier than installing it through a wall; however installing it into a door is more complicated than putting a pet door into a sliding door track. We recommend a contractor for installations that involve cutting into drywall. |

|

What is the flap size for the Endura Dog Doors for Walls-Large-Double Flap? The actual flap on the Large size Endura Flap is about 10"w x 20"h. However, the opening for the pet to use on the single flap is 10"w x 19"h and on the double flap is 10”w x 18”h (due to the thickness of two flaps). |

|

Can I just get the Endura wall kit? We do have those, but you will need to reach out to our customer service team. For other Endura replacement pet products, see Endura replacement flaps and parts. |

|

How much does shipping cost? Shipping is calculated at checkout. |

Warranty

Warranty Type: Lifetime

Duration: Lifetime of the product.

Coverage: Defects in materials and workmanship under standard regular use.

Exclusions:

Damage caused by misuse or not using the product as intended.

Improper installation.

Damage caused by chewing.

Product Details

Product Details

Printable Version

Printable Version

Difficulty

Difficulty

Steps

Steps

Time Required

Time Required

Flags

Flags